Metadata Management with Semantic AI

Smarter decisions powered by metadata. Create and manage metadata and transform information into meaningful, actionable intelligence with Semaphore, our no-code metadata engine.

The Semantic Layer for Your Digital Ecosystem

Capture enterprise knowledge, analyze structured and unstructured information to extract hidden facts and relationships, and augment and extend the reach of mainstream AI with Semaphore by Progress.

Ease of Use

A user-friendly platform that lets you effectively collaborate with subject matter experts and assign them tasks, so they can easily add their deep domain knowledge to the workflow.

Flexibility

The Data Catalogue can be built over time, adding new features as required and when new systems are included in the scope

Consistency

Semantics provides a “universal language” for describing disparate systems. This approach can be used to describe both business and IT concepts

Harmonization

The ability to normalise metadata definitions across systems

Coverage

The ability to extend Data Governance by providing a rich layer of consistent metadata across unstructured and textual sources

Understanding

The ability to present Data Governance concepts using the language and vocabulary of the business users

Semaphore Semantic AI Capabilities

Use Cases

Trends

Report

Report

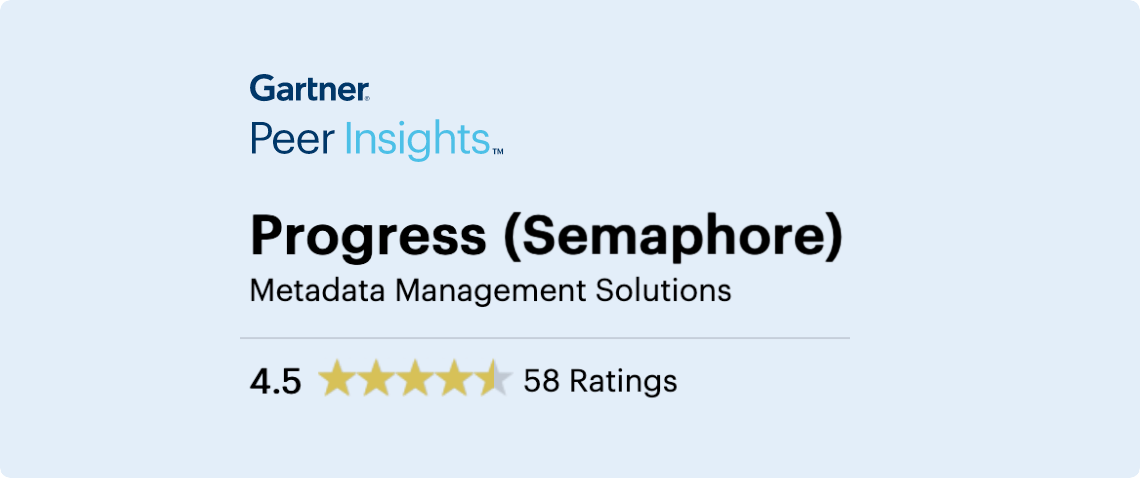

Analysts and Clients Recognize Us for What We Do Best

“Powerful, flexible product, especially for transparent AI classification.”

Knowledge Managment Specialist

Public Sector / Government

Flexible Licensing & Deployment

Deploy Semaphore on premises, as Software as a Service (SaaS), on demand, and in hybrid mode. License only the modules you need. Or, for complete data and metadata management, check out the full MarkLogic data platform with Semaphore built in.

Development

- Bundled Subscription Service

- Non-production use for demos, development, and capability evaluations

Business

- Bundled Subscription Service

- Business Solution for clients with departmental capacity requirements

Learning & Resources

Ready to Get Started?

Try Semaphore free for 30 days to see first-hand how our market-leading Semantic AI technology reveals smarter decisions faster and at lower cost.

.tmb-medium.png?Culture=en&sfvrsn=55963425_1)